LS Inventory

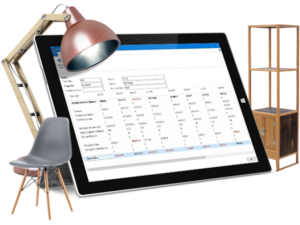

LS Inventory Management

Save time and money by

simplifying your inventory operations

One software system to cover all your inventory management needs and more! Manage your stock optimally, minimising inventory while reducing stock-outs, with a mix of manual and automated replenishment tools.

Manual replenishment with allocation planning

The LS Central Allocation Plan helps you

- Manage seasonal items

- Plan the buying process

- Allocate items to stores

- Plan buffer quantities for the warehouse

The system offers different levels of user control. For instance, retailers can use manual replenishment methods to push specific stock to stores or franchise partners.

Automatic replenishment with forecasting

Save time by automating basic replenishment tasks. The system can calculate the quantities to reorder for stores and/or warehouses, simplify item distribution and planning, lower item stock cost and increase item availability in all your warehouses and stores.

Multiple classes of forecasting methods help you catch all types of trends in sales history, including seasonality, holidays and annual events. The system also calculates safety stock levels based on variations in sales.

Open-to-buy functionality

Control the amount of capital invested in products during the sales cycle. The open-to-buy functionality empowers you to:

- Maintain control over which products are available in each store

- Manage sales and purchasing budgets

- Calculate the difference between required and available inventory, including inventory on hand, stock in transit and outstanding orders

total prediction

Why LS Central Inventory?

Replacing all the separate platforms you are using now. All data is collected in one central place, so you can track sales, stock and productivity in real time, in all your locations, from the back office.

Correct stock coverage

Find out how long stock will last you, and understand which items are under- and over-stocked.

Total visibility over inventory

Get an instant, clear view of all inventory available across the company, including laya-ways and transfer requests.

Stock planning per store capacity

Optimise your stock amounts and product mix based on how much stock each of your stores can carry.

Manage inventory on mobile devices

Carry out store inventory processes on handheld devices, including receiving and transfers of goods.

Assortment plan

Easily plan the assortment of items in your stores with an intuitive top-down approach using flexible store and item hierarchies.

The right variants in each location

The system uses historical sales data to calculate the right amount of products in each variant (size, colour, etc.), for each of your stores.